A reciprocating saw uses a back-and-forth motion to saw through wood, metal, or any combination of materials during demolition. Due to the nature of the motion, it creates a lot of vibration which manufacturers combat through various means. Pros use this tool over other types of tools for various reasons. Reciprocating saws come in various sizes and performance levels to match whatever needs cutting. Reciprocating saws come in many shapes and sizes, so the field of options can get a bit daunting. I’ll try to help you understand the various potential applications so you can know which reciprocating saw makes sense for your needs.

Editor’s Note: Check out the best reciprocating saw article to get our test results and top picks.

Sawzall vs Reciprocating Saw

Sawzall (saws-all, get it?) is just the trade name for a Milwaukee reciprocating saw. As the first manufacturer to bring these tools to market, users quickly started calling these by the Sawzall name. We cover the Sawzall vs reciprocating saw topic more thoroughly in another article.

How Does a Reciprocating Saw Work?

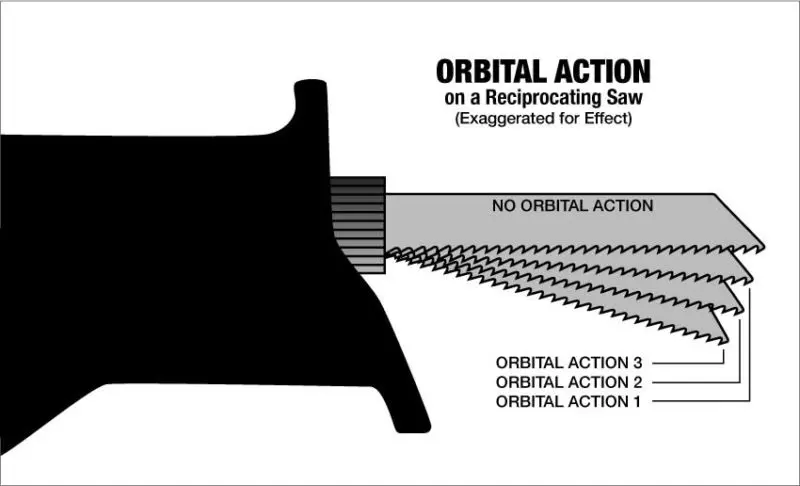

A reciprocating saw works by creating a back-and-forth sawing motion with a reciprocating saw blade. Some models let you turn on orbital mode which creates a circular forward cutting motion. This has the effect of cutting through wood more quickly during demo or wood-cutting.

You also want to consider vibration. When a tool throws a blade out and in at a very rapid speed, you get a lot of inertia. This has the effect of creating a massive amount of vibration in your hand as you use the tool. Some companies like Milwaukee, Flex, Skilsaw, and others utilize a counterweight to throw weight backward as the saw blade moves forward. Below is a flywheel module from a Sawzall reciprocating saw.

A reciprocating saw features a tool-free blade clamp that lets you load blades for wood, metal, or general-purpose cutting.

Uses of a Reciprocating Saw

Demolition Work

First and foremost, professional tradesmen use reciprocating saws for demolition (demo) work. That includes tearing out walls, opening up rough doorways and windows—even breaking apart pallets! The reason you want to use a recip saw or Sawzall for this type of work is that you can get excellent reach and extension across multiple 2x4s. Blades with carbide teeth also help you slice through nails and straps without having to stop.

Circular saws only cut a bit over 2 inches in depth. A reciprocating saw can use a 6-, 9-, or 12-inch blade. That lets you take care of some seriously deep cuts when demolishing old work.

Cutting PVC Pipe

Plumbers and irrigation experts can attest to the convenience of a reciprocating saw when cutting through PVC pipe. While hand cutters work great for small diameter pipe, larger pipes for drainage and other applications and Schedule 40 pipe benefits from the use of a nice reciprocating saw.

Many Pros I talk to prefer one-handed reciprocating saws for these tasks. You can place a solid grip on the material being cut while simultaneously having a secure hold on the tool.

Making Cuts in EMT or Rigid Metal Conduit

When it comes to EMT or rigid conduit, electricians love reciprocating saws for quick cuts. Fortunately, several manufacturers make great blades for both thin and thick metal. I prefer using blades with carbide teeth as they tend to last longer and reduce downtime. They are well worth the extra cost.

Black Pipe and Cast Iron

For either black pipe or cast iron, a reciprocating saw with a high-quality carbide-tooth blade works wonders. Before, you had to use chain cutters or diamond grit blades—both of which took forever to make cuts. Now, blades like the Milwaukee Nitrus Carbide Sawzall blades make this work easy. Even better, you can use them for more than one cut!

Cutting in a Window or Doorway

From Flush Cut blades to wood blades, use a reciprocating saw for clearing doorway jams and removing plywood when fitting windows into rough openings. While I’ve seen other tools used for these applications, the recip saw remains a favorite go-to tool. It requires very little skill, and the flexible blade lets you get up close and flush to the cut.

Cutting Branches

One of the more innovative uses of a reciprocating saw has to do with landscaping tasks. Several years ago, some manufacturers began making pruning blades for recip saws. These blades feature large teeth with low TPI counts (teeth per inch). They work extremely quickly and let you get through much larger branches than you could with traditional hand pruners.

What are the Types of Reciprocating Saws?

While you can technically make nearly any cut with any reciprocating saws (assuming you can get it into the space) some take much longer than others. You might find yourself holding down the trigger for minutes per cut. Just as bad, you could be cutting through something delicate with all the grace of a bull in a china shop. Just like Pop always said, grab the right tool for the job for the best results.

Compact One-handed Reciprocating Saws

Compact reciprocating saws come in two varieties. The most popular is a one-handed style. Its design lets you use two hands to stabilize the cut. It’s also light and balanced enough to easily use it with one hand.

These saws are great when you need to cut pipe or similar material that isn’t very stable. You can stabilize the material with your free hand and work the saw with the other.

One-hand models have the slowest cutting speeds thanks to shorter stroke lengths (around 7/8″) and often slower stroke rates (less than 3000 SPM). Paired with a high tooth count blade in the 14 – 18 TPI range, they’re excellent for cutting EMT, PVC, copper pipe, and other thin materials.

Because of their small size and lighter weight, compact reciprocating saws (or Hackzalls) are great for electricians and plumbers who often have to cut in awkward spaces. The one-hand design lets them work around the other materials or confined spaces more conveniently.

While not great for wood cutting on the construction/demolition side, I like one-handed saws paired with a low TPI carbide pruning blade for landscaping. It can cut a much thicker branch than standard shears. It can also save you from having to get out a chainsaw in many cases.

If you’re looking for the most compact models possible and don’t mind trading off some cutting speed, there are several 12V models to choose from. The best Sawzall models in the one-hand class use 18V/20V max batteries (or close to it, such as 24V max). And, yes, you can still find a few corded models.

Compact Two-Handed Reciprocating Saws

Another type of compact reciprocating saw is a two-handed model. It looks similar to a traditional Sawzall but “squashed”. This makes it shorter from tip to tail and taller from top to bottom. Some of these saws can be shorter than one-hand models but tend to be heavier.

Not as common as one-hand models, you can still find these in corded or cordless models. It’s a good type of reciprocating saw to have on hand when you’re trying to reach between studs or other tight spaces where your standard Sawzall won’t fit.

The performance of a two-hand model typically exceeds that of one-handed reciprocating saws. They often move closer to 3000 SPM and have longer stroke lengths in the 1″ range. We find these models great for cutting PVC, EMT, copper pipe, and other thin materials. In addition to cutting quickly, you can also cut wood in locations where your full-size reciprocating saw won’t fit.

Two-hand compact models do their best work as a supplement to full-size saws. They’re not as useful as one-hand saws for plumbers and electricians, but they can get remodelers out of a jam.

Medium-Duty Sawzalls

The best Sawzall models in the medium-duty class include 10 – 12-amp corded units and standard, non-advanced cordless options, usually on 18V/20V max batteries (including 22V and 24V max). These saws take on a traditional Sawzall look—much longer from tip to tail and pretty short from top to bottom with a D-handle at the back.

They make much faster cuts than compact saws. Much of this has to do with stroke rates around 3000 SPM and stroke lengths between 1-1/8″ and 1-1/4″. They can handle cutting the same thin materials as the compact models but with faster cutting speeds. They’re also much more reasonable as a primary option to cut wood.

Longer and heavier than compact models, but shorter and lighter than their heavy-duty and super-duty brothers, these are great all-around reciprocating saws in a variety of situations.

For DIYers who only need a Sawzall occasionally, one of these reciprocating saws can be the only model you need to own. On the professional side, these are a go-to option for light to medium-duty demo work and a primary option for overhead work.

Heavy-Duty Reciprocating Saws and Sawzalls

Sitting in between the medium-duty class and the super-duty class is a very small group of heavy-duty Sawzalls. They’re mainly 13-amp corded models and some of the advanced cordless models fit better here than in the super-duty class.

These saws serve as a middle ground between the other two traditional groups. They give you more power and cutting speed than the medium-duty class with a lighter weight than the super-duty saws.

You see faster cutting speeds in all materials, but it’s not the best reciprocating saw for every job. On the high end, some really tough cuts such as roofing and layered materials are better left to stronger saws.

On the light end, all that power can be overkill for some of the thinner materials if you want to maintain any kind of control. While you can feather the variable speed trigger, I don’t meet a lot of Pros who cut at less than full speed!

Most of the reciprocating saws in this class are designed with professionals in mind. They’re good all-around saws if you need to use one occasionally and only want to buy one saw instead of having both medium-duty and super-duty tools.

Super-Duty Sawzalls

As you consider different types of reciprocating saws, super-duty reciprocating saws are the muscular beasts at the top of the food chain. Usually, 15-amp models represent the most advanced and powerful saws. A smaller number of 14-amp saws also fall into this class.

Even though I typically see the same stroke length and rate as the medium and heavy-duty groups, the more powerful motors help keep cutting speeds even higher. This especially helps as materials get tougher and thicker.

As the cream of the crop, this class has the best features, including variable speed dials, orbital action modes, and advanced vibration control. You might find some of those here and there with the smaller saws, but they’re much more prevalent at this level.

As you may have guessed, the trade-off is that they’re the biggest and heaviest models as well.

Like the heavy-duty class, these are not the Sawzalls you normally use to make a few cuts in thin materials. They’ll give you the greatest benefits in the toughest, thickest materials you need to cut. Pair these tools with something like the Milwaukee Torch with Carbide Teeth thick metal blades, and you can cut rebar, cast iron, and even vehicle frames more easily than with other purpose-built tools for the same jobs.