Back in early 2017, OSHA announced new silica dust regulations that would affect the entire construction industry. Bosch proactively contacted us to start the push toward education before the September 23rd deadline. That date has come and gone, but there’s still plenty of confusion running around about what you need and what you don’t. Many manufacturers like Bosch, Makita, and others set up specific pages on their websites to help Pros navigate OSHA Table 1 compliance.

There’s a lot of information to digest. We break it down so you know exactly what you’ll find for the kind of work you do.

Table of Contents

- What is OSHA Table 1 Compliance?

- Choosing the Right Tools for OSHA Table 1 Compliance

- OSHA Table 1 Compliance for Concrete Drilling

- Concrete Demolition and Table 1

- Using HEPA Filters for Table 1 Compliance

- Silica Dust Regulations for Surface Grinding

- Concrete Cutting

- Masonry and Tuckpointing OSHA Silica Dust Compliance

- Using Objective Test Data

- More Silica Dust Resources

What is OSHA Table 1 Compliance?

OSHA Table 1 Compliance refers to adhering to the Occupational Safety and Health Administration’s guidelines for controlling silica dust exposure in the workplace. OSHA Table 1 outlines specific tool and process requirements for construction tasks that generate silica dust, including but not limited to, cutting, grinding, drilling, and sanding of concrete and masonry.

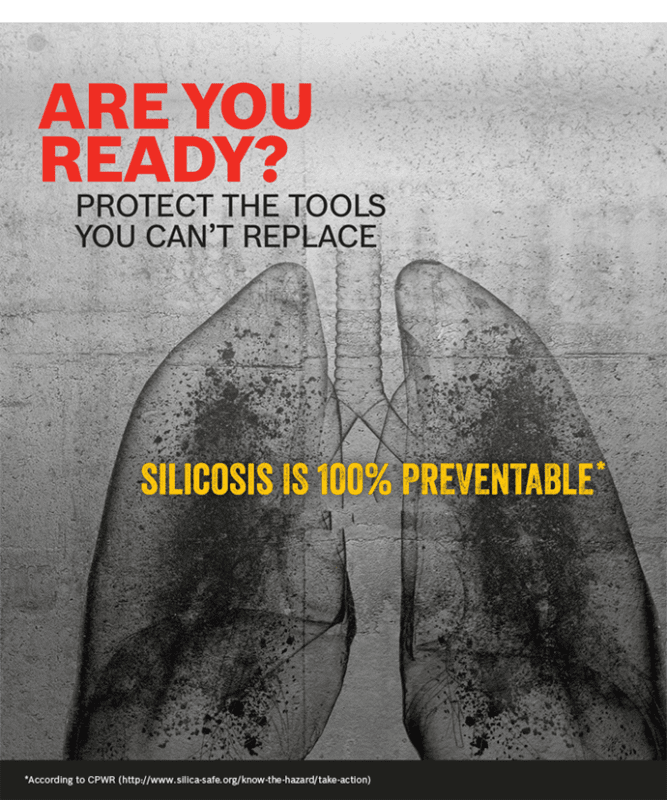

These requirements include using dust extractors and providing appropriate personal protective equipment (PPE) including respirators. Compliance with OSHA Table 1 not only avoids steep fines, but it also protects workers from the harmful effects of breathing in silica dust. That can cause silicosis, a potentially fatal lung disease.

Choosing the Right Tools for OSHA Table 1 Compliance

OSHA silica dust compliance requires choosing the right tools and accessories for the job. From the tool doing the work to the accessories it needs and attachments to dust extraction, Table 1 provides pre-approved packages to help you know you’re compliant before the job ever starts.

Each manufacturer can submit various tools and packages for Table 1 approval. Companies like Hilti, Bosch, Milwaukee Tool, DeWalt, and others have gone through this process for many of their products. This ensures construction workers and companies don’t have to worry if they’re in compliance when using the tools as directed.

OSHA Table 1 Compliance for Concrete Drilling

A site covering Table 1 might pair various hammer drills, and SDS-Plus/Max rotary hammers with various corded and cordless dust extractors or accessories.

All major manufacturers with serious concrete tools provide Table 1 compliance guidelines and recommendations.

With some tools, having the right accessories and attachments is all you need. With many hammer drills, for example, a dust shroud fits the bill. These attach to the end of your dust extractor hose. With these in place, you just turn the vacuum, stick the shroud to the wall, and start drilling. The shroud and dust extractor take care of the dust.

With rotary and spline hammers you can use hollow drill bits like Bosch Speed Clean or Hilti Hollow Core bits. You’re collecting the dust at the point of creation with those, greatly simplifying the process.

If a manufacturer doesn’t make a specific bit size, or you want a different option, dust shrouds can also work. Some tools even have options for the use of onboard dust extractors.

Onboard dust extraction lets you drill into walls—even overhead—without dealing with excessive silicon dust exposure. We love anything that limits when and how you have to wear a mask. In some cases, it’s always good to have extra protection. Power tools have come a long way in just a handful of years. If you can eliminate a bulky respirator and replace it with an N95, that’s a huge win for concrete professionals.

Concrete Demolition and Table 1

On the demolition side we also see OSHA Table 1 compliance. SDS-Max rotary hammers and demolition hammers and breakers specify products that meet the required dust extraction specs. Attachments go close to the point of contact to catch the dust that shoots out while bigger chunks fall away.

Dust extraction options remain the same with these tools. You may still need respiration when doing indoor demolition or when working more than 4 hours on a shift.

Table 1 Compliance Tip: 4 hours of demo work per shift doesn’t mean that you’re tasked with demo work for 4 hours. It means that you’re doing 4 continuous hours of breaking in a shift. It doesn’t count the time that the tool isn’t actively working on demo. That’s a big factor when it comes to whether or not you’ll actually need a respirator.

Using HEPA Filters for Table 1 Compliance

OSHA Table 1 seems clear when you need to use a dust extractor with a filter cleaning mechanism. It gets a bit more confusing for consumers when it comes to the filters within those tools.

In reality, Table 1 only requires a HEPA filter for two types of applications. The first involves hole cleaning when using epoxy anchors. The other has to do with surface prep when using grinders or walk-behind machines. That’s pretty much it. Check out our article on when you need a HEPA filter for even more info.

Silica Dust Regulations for Surface Grinding

It should come as no surprise that you can find plenty of Table 1 options in the surface grinding category. One way to go is with a concrete surface grinder that includes a dedicated dust collection shroud. That removes the need for additional accessories. Just connect it to your dust extractor and check your respirator requirement.

The rest of the grinders are broken into the 5-, 7-, and 9-inch classes. Those are important distinctions because of dust extractor requirements.

Table 1 Compliance Tip: You need 25 CFM for every 1″ of grinder wheel. A 5″ grinder needs 125 CFM minimum, while a 9″ grinder needs 225 CFM. However, it’s about the wheel size, not max wheel size. If you use a 7″ wheel on a 9″ grinder, you only need 175 CFM.

In most cases, you need to add a dust shroud to the grinder. Some manufacturers recommend using the same 7-inch shroud and wheel for both their 7- and 9-inch grinders. That keeps you at needing just 175 CFM on your dust extractor since you’re working with a smaller wheel than the 9-inch grinder can potentially accept.

One other point, some dust extractors top out at around 150 CFM. That’s great for most portable dust extractors. When moving up to the 7- or 9-inch class, you need to use more powerful vacuums.

The respiration requirements are the same as with demolition. If you’re working indoors or for more than 4 continuous hours, you’ll need to wear a respirator.

Concrete Cutting

Table 1 compliance for concrete cutting solutions is very similar to the surface grinding category. You have fewer grinders to choose from. That may have contributed to the introduction of the 6-inch grinder class.

The attachments change from horizontal to vertical shrouds to accommodate dry concrete cutting. We see that many 6-inch grinders will use a 5-inch shroud. This mimics how compliant 9-inch grinders may drop to 7-inch cups for surface grinding.

Dust extraction options remain unchanged, including the requirement for additional dust extractor CFM on the 7″ and 9″ grinders. Again, respirators are only required for indoors and 4+ hours of continuous use.

Masonry and Tuckpointing OSHA Silica Dust Compliance

Tuckpointing is our last application-specific category for OSHA Table 1 compliance. There are a couple of tuckpointing models to choose from that don’t require additional accessories. You also have 4-1/2″ to 6″ grinders that work well with shrouds.

Dust extraction stays the same, and manufacturers like Bosch are able to cover all of the grinder sizes in this category. What takes a drastic change here is respiration requirements. Whether you’re tuckpointing for 30 seconds or all day, you have to wear a respirator.

Using Objective Test Data

When drilling, chiseling, grinding, cutting, or tuckpointing in concrete, it’s helpful for manufacturers to have objective test data compliance letters. With these prepared in a downloadable format for various accessory packages, tradesmen and companies can access them when needed. Ideally, you’d find the one you need and download or print it.

More Silica Dust Resources

Have a crew member that’s just not taking silica dust seriously? Or maybe you’re not so sure why it’s such a big deal? Check out this easy-to-read breakdown of the dangers of silica dust exposure.

You can also head over to the 3M website to check out their respiration solutions.

A list of compliant tools and accessory combos is handy to have on hand at the jobsite. A printed copy also makes all that information much easier to access or even digest. You want to avoid having to scroll through a website on the jobsite. Either way, it’s a great resource to have on hand. Don’t forget that you can find additional resources on the OSHA website.