What is orbital action in a reciprocating saw and do you need it? That’s the question we’re looking at today and it’s a common one. With a few notable exceptions, most manufacturers weren’t adding this feature to their cordless reciprocating saws. This led to some confusion as to whether or not you actually need it to cut quickly.

Table of Contents

What is Orbital Action?

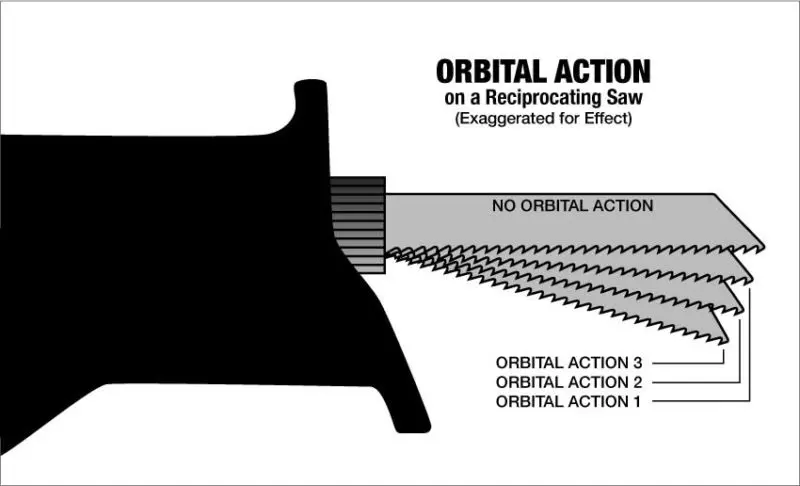

The orbital action setting on a reciprocating saw introduces an elliptical motion to the standard back-and-forth sawing. This more aggressive action removes more material when cutting through wood. With a more aggressive cut, however, comes additional vibration. As a result, you should never use this mode when cutting metal or PVC.

Some saws combat the additional vibration caused by a reciprocating saw with a counterbalance. This takes the form of many different types of systems. Skilsaw Buzzkill technology looks like this:

The vibration-reducing flywheel on the Milwaukee Sawzall looks like this:

When Did Reciprocating Saws Start Using Orbital Action?

You can trace orbital action back to a patent filed in 1982 by Black & Decker Inc. for application on a jigsaw. While not definitive, it shows the technology goes back around 40 years or so. A couple of years later, another patent applied the feature to a reciprocating saw.

When Milwaukee Tool invented the Sawzall in 1951 (shown below), it lacked this feature. At the time, just getting the blade to move back and forth satisfied a lot of needs as an electric version of a hacksaw.

When to Use It

Orbital action is suitable for aggressive cuts in wood when a rough cut to remove material quickly is called for. However, it’s not recommended for cutting metal, or when making highly precise cuts where the blade has to be kept perfectly perpendicular to the work surface.

Using orbital action is especially helpful in a reciprocating saw when doing demolition work. You cut a lot faster and with less effort. Better quality saws give you the option to adjust the saw with a lever, knob, or switch to change from straight to orbital or to some degree in between. While you can pick your level of aggressiveness on these reciprocating saws, most Pros typically slam it either on or off. To sum it all up:

When to Use Orbital Action

- Making imprecise cuts in clean wood

- Demoing nail-embedded wood

- Cutting multi-layered materials for demolition and renovation

When NOT to Use Orbital Action

- Cutting PVC

- Cutting through EMT or other metal

- Making more precise or accurate cuts in wood

Does Orbital Action Really Matter?

I have some evidence to work with aside from manufacturer claims about orbital action. While testing the best reciprocating saws I got my hands on models both with and without this type of cutting mode. During testing, saws with orbital action typically cut the fastest in wood. Keep that in mind if you primarily demo wood with nails.

However, a couple of other well-designed saws didn’t lag too far behind. So what about a more apples-to-apples approach? Some objective testing helps me recommend exactly when to use orbital action.

I had a Bosch 18V reciprocating saw run through the same test several times with and without orbital action engaged. Using just technique, and see-sawing the tool through the cut, the closest time still trailed the fastest orbital speed by roughly 2.5 seconds.

The results of more scientific testing are even more telling. Using the same weight each saw had equal downforce while testing. The Bosch cut through a 2 x 12 pressure-treated board embedded with five 16D nails in 31.83 seconds. Switching over to orbital, the time was just 18.28 seconds—a drop of just over 13.5 seconds. That makes the non-orbital action nearly 75% slower!

The Bottom Line

Letting the saw and blade do the work is always the way to go when cutting, even in demo work. When you do that, this features has a massive advantage in wood cutting. Even if you try to beat it with technique, you’ll still fall short and you’ll work a lot harder trying.