With all the focus on what tools are Made in the USA, we wanted to take stock of what’s actually manufactured and assembled here in the United States and celebrate the companies putting American workers to work. You quickly run into two problems with that, of course. One, we can’t possibly include everybody, and two, the rules keep changing regarding when you can actually say a product or tool is Made in America.

Want to watch this in video format? Click here—and subscribe!

On that first problem, we simply ask you to follow along—we’re going to go through our list in alphabetical order. If we miss a company that makes their tools or equipment in America—let us know in the comments below.

What Tools Can Say ‘Made in the USA’

Now, regarding what tools are Made in the USA—for real. We definitely need to back up a bit before we dive in. In June of 2020, the FTC announced a Notice of Proposed Rulemaking for a Made in USA Labeling Rule.

The proposed rule would apply to labels on products that make unqualified or broad representations of Made in USA claims. It would basically prohibit marketers from making unqualified MUSA claims on labels unless:

- Final assembly or processing of the product occurs in the United States;

- All significant processing that goes into the product occurs in the United States; and

- All or virtually all ingredients or components of the product are made and sourced in the United States.

Now, frankly, we’re not in a position to verify all of the components of products. So, we’re going to go with what we know or can discern…and celebrate the following companies who employ Americans in making products right here in the States.

Ariens

AriensCo began in 1933 when Henry Ariens and his three sons developed the first American-made rotary tiller. They did this at a time when other manufacturers were experimenting with imported tillers. Since then, the company has been passed down, son to son, for four generations. Over the course of nearly 90 years, the company’s zip code, along with their CEOs’ last names have remained the same.

AriensCo is headquartered in Brillion, Wisconsin, a small town with only 3,200 residents. What started as a simple idea in a garage has evolved into a multi-brand company that employs more than 1,700 people. And the best part? The company is still owned and operated by the same family that started it all.

Briggs & Stratton

Briggs & Stratton Corporation, headquartered in Milwaukee, Wisconsin, is the world’s largest producer of gasoline engines for outdoor power equipment. They also design, manufacture, and market power generators, pressure washers, lawn and garden, turf care, and job site products through their Briggs & Stratton, Simplicity, Snapper, Ferris, Vanguard, Allmand, Billy Goat, Murray, Branco, and Victa brands. Briggs & Stratton designs, manufactures, markets, and services its products in over 100 countries on six continents.

BUT—Briggs & Stratton makes 85% of its products right here in the U.S.A. with both U.S. and globally sourced components. The company has manufacturing plants in Statesboro, GA, and Auburn, AL where it produces its V-Twin Vanguard engines. They also make engines and more at their Poplar Bluff, MO; and Milwaukee, WI plants. (Briggs & Straton shuttered its Murray, KY plant in 2020—the same year they went through Chapter 11 bankruptcy). The company consolidated its production of small vertical-shaft engines into its Poplar Bluff, Missouri facility.

Finally, Briggs & Stratton opened a new 78,000-square-foot advanced battery manufacturing facility in Tucker, GA in 2021.

Channellock

Channellock started making high-quality hand tools back in 1886 when George B. DeArment, a blacksmith from Evansburg, PA, began hand-forging farrier’s tools in a small factory.

Over 130 years later, the fifth generation of the DeArment family still runs Channellock. The company is based out of two facilities totaling 260,000 square feet, in Meadville, PA where they employ more than 350 full-time employees. The company manufactures more than 75 different sizes and types of pliers.

To our knowledge, Channellock still makes ALL their pliers in Meadville where they ship out to more than 4,000 U.S. wholesale and retail customers across 45 countries.

Crescent Tool

Crescent Tool covers brands like Wiss, H.K. Porter, Jobox, and—of course—Crescent Tools.

Tools made in the USA include Crescent Wiss Next Generation Aviation Snips; Crescent H.K. Porter 14″ PowerPivot Center Cut Double Compound Action Bolt Cutters; and the Crescent JOBOX Crossover Truck Box and JOBOX chests.

Wiss and H.K. Porter products, and a few others, are made in Lexington, S.C., while they build JOBOX products in Jonesboro, Ark.

Cub Cadet

Since 1961, Cub Cadet has built lawn and garden equipment in America at the company’s manufacturing facilities in Ohio, Mississippi, and Tennessee. Cub Cadet also designs and engineers products in Valley City, Ohio—the headquarters of its now global operation under MTD Products.

DeWalt, Craftsman, Stanley Black & Decker

Stanley Black and Decker (or SBD) includes almost too many brands to count. Most are familiar with the DeWalt, Craftsman, Stanley, Black + Decker, Bostitch, Irwin, Porter-Cable, Mac Tools, Proto, and Lenox brands—to name just a handful.

Taking a virtual tour around the country, SBD claims 48 U.S. manufacturing facilities. The company maintains these facilities across two dozen or so states where they collectively employ over 18,000 U.S.-based workers to make products in America using global materials.

We actually visited one of DeWalt’s facilities in North Carolina back in 2016, but the company has expanded its USA-based manufacturing significantly since then.

Estwing

Since 1923, Estwing, a family-owned company has designed and manufactured claw hammers, axes, specialty tools, and pry bars for both tradesmen and craftsmen.

Estwing manufactures a majority of their hammers and hatchets in Rockford, Illinois.

Forrest Manufacturing Company

Founded in 1946 by Albert Walter Forrest, Forrest Manufacturing is based out of Clifton, NJ. The company remains family-owned and operated. To this day, their skilled workers continue to make every blade and dado in the U.S.A.

FLIR Systems

FLIR Systems is based in both Wilsonville, Oregon and Arlington, Virginia. The company started back in 1978 developing high-performance, low-cost thermal imaging systems for airborne applications. FLIR designs and makes many of its products in the USA. It also serves as one of the largest manufacturers of high-level thermal imaging products in America.

The company has manufacturing and R&D facilities in Goleta, California; North Billerica, Massachusetts; Bozeman, Montana; Stillwater, Oklahoma; Freeport, PA; Oak Ridge, Tennessee; and West Lafayette, Indiana. FLIR employs more than 1,600 people in the United States alone. Oh, and if you’re curious, FLIR stands for Forward-Looking InfraRed.

Generac

Founded in 1959, Generac was the first company to engineer affordable home standby generators. They also claim the first engine developed specifically for the rigors of generator use. Currently, Generac claims to be the largest portable generator manufacturer in North America.

In 1996, the company added their third manufacturing plant in Eagle, Wisconsin which they later expanded. Three years later, they completed a 135,000-square-foot manufacturing facility in Whitewater, Wisconsin. It produces Generac automatic home standby, RV, and telecom generators as well as air-cooled engines.

Most recently, in 2012 Generac re-purchased and moved production of its portable generators back to its Jefferson, WI manufacturing facility.

Greenlee

Greenlee, a brand of Emerson Electric, employs US workers in seven manufacturing facilities—at least two of which are in the USA. Their Genoa, IL facility opened up back in 1948 and manufactures commercial bending and pulling tools for electricians. It currently employs 73 people while their Louisville, KY facility has a staff of 80 and supplies metal fabricated products, components, sub-assemblies, and weldments for all Greenlee products. In all, they produce over 300 products at this plant.

Hardcore Hammers

Hardcore Hammers was started by two brothers dissatisfied with the way standard hammers wore out quickly. The company now manufactures hammers, hatchets, and axes in Shawnee, KS. Even the source material comes from USA facilities. The steel for the hammer heads, hatchets, and axes comes from foundries and companies in Wisconsin and Illinois. The American hickory handles are turned in Alabama & Arkansas.

Hobart Welding Products

Hobart Welding Products makes many of its welders in its Appleton, WI manufacturing plant. It’s a sister company to Miller Electric—and both are wholly owned by parent company ITW or Illinois Tool Works.

Ideal Industries

J. Walter Becker started Ideal Industries back in 1916. Headquartered in Sycamore, IL, Ideal now includes brands such as Casella, Anderson Power Products, Wavetek, SK Tools, and Cree Lighting.

Ideal-branded products include more than 6,000 SKUs. Their Made-in-the-USA products include Wire-Nut Wire Connectors, Yellow 77 Wire Pulling Lubricant, and T-Stripper Wire Strippers. Ideal makes all of these in their Sycamore plant. They also forge Ideal pliers and wrenches in their Colorado facility and produce a rather robust Made in the USA screwdriver line across their Illinois, Colorado, and Pennsylvania plants.

John Deere

Deere & Company was founded in 1837 and continues to provide advanced products, technology, and services for agriculture and construction professionals. Their products seem to show up everywhere you see people producing things like food, fuel, shelter, and infrastructure.

John Deere manufactures their Gator Utility Vehicles and X-Series Lawn Tractors at their Horicon, WI factory. In Greeneville, TN they produce the 100 Series Lawn Tractors, S240 Lawn Tractors, and Z300 & Z500 Zero Turn Mowers

They make their step-up Z900 ZT Mowers in Fuquay-Varina, NC. John Deer manufactures their 1, 2, 3, and 4 Series Compact Utility Tractors in Augusta, GA.

In addition to this, John Deer has multiple factories throughout the Mid-West that manufacture large Agricultural tractors, sprayers, and combines.

Finally, John Deere also manufactures a variety of professional turf industry equipment across the country.

Johnson Level

Based out of Mequon, WI, Johnson Level has made leveling, marking, and layout tools for over 70 years.

Now part of the Hultafors Group in Sweden, the company still has over 70 SKUs made in America, including levels, squares, carpenters pencils, and laser products.

Klein Tools

Klein Tools founded its company back in 1857 and still makes the vast majority of its products in the USA. The company has also invested in 4 new U.S. manufacturing facilities in just the past 10 years as well as investing heavily in new equipment and tooling to expand both the capacity and quality of these and its existing plants.

While Lincolnshire, IL houses their corporate headquarters, Klein also has facilities in Mansfield, TX; Elk Grove Village, IL; Bolivar, NY; and Fort Smith, AR.

Klein also plans to invest more than $100 million to expand US-based manufacturing.

Made in the USA Knife Manufacturers

We’re definitely not going to hit all of the knife manufacturers in the USA, but let’s look at at least a few.

Benchmade Knives

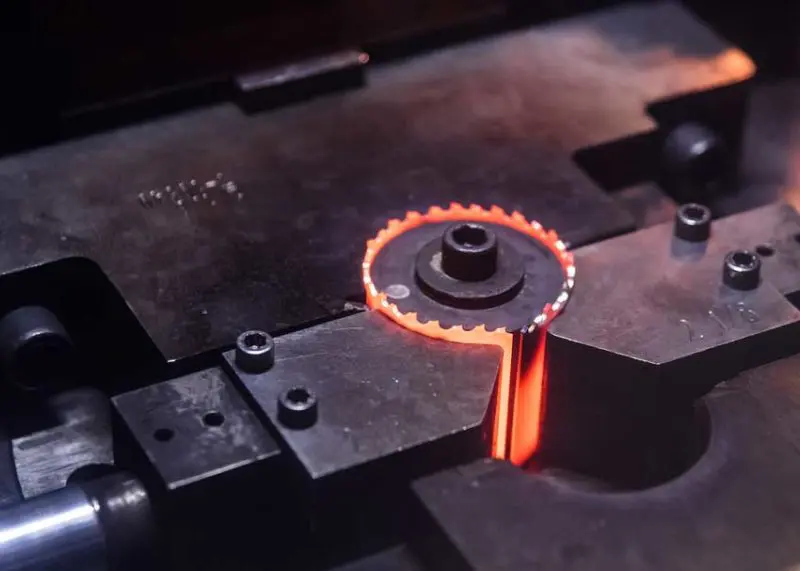

The Benchmade Knife Company is based in Oregon and was founded by Les de Asis in 1987. The company may have been the first to employ high-tech tools like high-power laser cutters and low-tolerance CNC machinery into the knife-manufacturing process. Benchmade makes all of their knives in their 144,000 sq. ft. Oregon City, Oregon manufacturing facility.

Buck Knives

Buck Knives manufactures its products in Post Falls, Idaho. The company was started by a young Kansas blacksmith apprentice named Hoyt Buck who was looking for a better way to temper steel so it would hold an edge longer. His technique produced the first Buck Knife in 1902. CJ Buck is now the 4th generation family member to run Buck Knives as CEO, President, and Chairman.

Kershaw & Zero Tolerance Knives

KAI USA Ltd., the parent company behind Kershaw and Zero Tolerance Knives builds dozens of their knife models in their Tualatin, Oregon factory. Pete Kershaw founded the company in 1974, making hunting knives in a cement plant in Lake Oswego, Oregon. Kershaw’s USA-made models include the Leek, Blur, Link, Scallion, Chive, and Launch models.

The Zero Tolerance or ZT brand first made its appearance in 2006 as a Made-in-USA line of hard-use knives designed for professionals in the military, law enforcement, and first responders. Both Kershaw and ZT use high-quality American-Made steels like 420HC, 20CV, S30V, and S35VN.

Kraft Tool Co

Ron Meyer and Si Kraft established the Kraft Tool Co. in 1981. Thirty years later, Kraft Tool continues to manufacture Made-in-the-USA tools for the professional cement finisher, brick mason, asphalt paver, tile setter, plasterer, and drywall craftsman. The Kraft Tool Co acquired several companies and brands over the past 39 years including W. Rose, Sands Level and Tool, Superior Tile Cutter, Inc, and Hi-Craft.

Kubota

The Kubota Corporation introduced its first tractor to the United States in 1969—the 21 HP L200 sub-compact tractor. It was pretty much an instant success.

Kubota Manufacturing of America, or KMA, was formed in 1988 as the company’s North American manufacturing base. KMA manufactures and assembles Kubota lawn tractors, zero-turn mowers, sub-compact tractors, utility vehicles, loaders, backhoes, and other implements. The company employs over 1,200 American workers.

Kubota Industrial Equipment (or KIE) manufactures compact tractors and tractor implements including loaders and backhoes.

All told, more than half of all Kubota-branded equipment sold in the United States is manufactured or assembled in their Gainesville and Jefferson, Georgia facilities.

Leatherman

You can’t discuss what tools are Made in the USA without bringing up Leatherman. Leatherman began with an order for 500 tools from Cabela’s back in 1983 when they launched the first Leatherman tool. Originally called the “PST”, or Pocket Survival Tool, it jammed 13 different tools into a folded-up 5 ounce, 4-inch toolbox. Over the next decade, Leatherman sold over one million of these multi-tools.

Currently, the company continues to build and manufacture all of its tools in Portland, Oregon.

Lenox Tools

We mentioned this company earlier as part of SBD, but Lenox Tools has an interesting history of its own. It began in 1915 as the “American Saw and Manufacturing Company” with just 10 employees. Back then, they made hacksaw blades. Over 100 years later, Lenox makes industrial saw blades, hand tools, power tool accessories, and other products. The company still, however, designs, tests, and manufactures products in East Longmeadow, Massachusetts using global materials.

Makita

Since 1985 Makita has produced products here in the U.S.A. at a facility just outside of Atlanta in Buford, Georgia. The Buford facility, officially titled the Makita Corporation of America (MCA), operates capital equipment for both manufacturing and assembly and produces Makita products destined for users and dealers across the U.S.A. and worldwide. To address continued growth here in America, Makita recently added nearly 1 million square feet of distribution and training center space with new facilities in Texas and Nevada. MCA is part of Makita’s global manufacturing network consisting of 10 factories in 8 different nations.

Malco Tools

Malco Products got its start in 1950 when Mark W. Keymer, a young steel supply salesman, decided to manufacture and market a pipe crimper he had invented for use in installing sheet metal ductwork. Decades later, early Malco crimpers, seamers, notchers, and punches have since been joined by hundreds of other specialty tools——nearly all of them made in the company’s Annandale, Minnesota plant. That includes turboshear drill attachments, Turbo Crimpers, Hole cutters, Andy and Max Snips, Seamers, and Mini Brakes.

Most recently, Malco also has expanded to a former Vise-Grip plant in DeWitt, Nebraska, where they’re working on a new line of Made in USA tools

Matco Tools

Matco Tools, a subsidiary of Fortive Corporation, began in 1946. Since 1979 they’ve sold automotive tools and products directly through a network of independent franchised tool trucks.

Miller Electric Mfg

Miller grew from a one-man operation in 1929 to the world’s largest manufacturer of arc welding products.

Based in Appleton, WI, the company manufactures MIG, TIG, and stick welders, engine-driven welders, plasma cutters, generators, and wire feeders.

Miller is a sister company with Hobart Welding and wholly-owned by ITW (Illinois Tool Works).

Milwaukee Electric Tool Corp

Milwaukee Tool has manufactured products in the USA since 1924, so they’ve got a rich American history. The company has manufacturing facilities in Greenwood & Jackson, MS; and Mukwonago, West Bend, and Sun Prarie, WI where they produce a variety of products including LED lights, step bits, corded SawZalls, large drills, SawZall blades, hole saws, bandsaw-and-multi-tool blades, as well as levels and squares.

Milwaukee also has plans to expand with a location in Cookeville, TN. In 2020 alone the company invested over $100 million and created 350 new jobs in the US.

In the works, Milwaukee also plans to manufacture hand tools in a new facility in West Bend, WI. This plant focuses on tools for electricians, plumbing & mechanical trades, and utility linemen.

M.K. Morse

M. K. Morse makes blades. Lots of blades. For almost every cutting application and tool you can think of. They service plumbers, electricians, carpenters, industrial manufacturers, and steel service centers.

The company manufactures nearly all of its products in Canton, Ohio. This facility has undergone a number of expansions over the years as the company developed a unique integrated manufacturing approach. It lets them ship most orders for standard stock products within 24 hours.

Occidental Leather

Since 1980, Occidental has manufactured quality leather tool belts, bags, and pouches for tradesmen. They honestly make the best tool belts in our opinion. Aside from the phenomenal build quality—which we have experienced first-hand—the best part includes the fact that all Occidental designs and manufactures all their tool bags, pouches, and tool belts in Sonoma County, California.

Proto Tools

Proto was founded in 1907 by Alphonse Plomb, Jacob Weninger, and Charles Williams as the Plomb Tool Company. It started as a small blacksmith shop making chisels in Los Angeles. In 1933, Proto (then known as “Plomb”) released what is widely thought to be the first combination wrench. Now, Proto fits into the Stanley Black & Decker group of companies.

Opened in 1986, Proto’s Dallas, TX manufacturing facility manufactures Proto and Blackhawk sockets, wrenches, drive tools, and torque wrenches. This includes calibration as well as the associated heat treatment, and plating processes.

Ridgid Tools (Emerson)

The Ridge Tool Company incorporated in Elyria, Ohio back in 1923. It began with the introduction of the now-iconic Ridgid pipe wrench, a tool still in use today. In 1966 Ridge Tool Company became part of Emerson Electric. To this day, the company still makes press jaws, pipe wrenches, roll grooving tools, threading dies & threaders, pipe cutters, hole-cutting tools, handheld power drives, and pipe bevelers in their Elyria plant.

Ridgid also makes sectionals, jetters, and FlexShaft drain cleaning equipment at their Orange, VA location.

Rolair Systems

As a third-generation manufacturer located in the heart of Wisconsin, Rolair has done nothing but build quality compressors since it began in 1959.

They assemble all of their belt-driven models, including both portable and stationary air compressors, as well as some of their direct drives, at Rolair’s facility in Hustisford, WI. The company assembles over 90% of its compressors in the USA.

Note: SK Professional Tools was acquired by GreatStar Tools USA on October 28, 2021 (SK was formerly part of Ideal Industries). GreatStar Tools USA is based out of Hangzhou, China.

Snap-on Tools

Nearly anytime we bring up what tools are Made in the USA, Snap-on gets mentioned. In 1920, Joseph Johnson, an engineer from Milwaukee, and his co-worker, William Seidemann made the very first Snap-on tools. They spent weekends using crude bending jigs and pure muscle to fashion two sample sets of five handles and ten sockets.

Snap-on currently makes many of its ratchets, wrenches, screwdrivers, roller cabinets, sandblasters, and certain diagnostic tools in its Kenosha, WI manufacturing facility.

Southwire Tools

Southwire Company had its founding as a manufacturing company in Carrollton, Georgia in 1950. They have facilities nationwide with more than 7,000 employees. The company produces everything from wire and cable to hand tools and equipment. Southwire’s Made In America hand tools program features an extensive line of products made in the USA—part of their commitment to US manufacturing. This also includes their Seatek Series, Sumner Manufacturing Co. product line, along with a majority of Southwire extension cords and contractor equipment product categories.

A recent addition, the Maxis XD1 Extreme Duty Circuit Puller marks one of the company’s latest Made-in-America products. They produce that tool in Phoenix, AZ.

Starrett

In 1880, Laroy Sunderland Starrett invented and made the world’s first combination square in Athol, Massachusetts. 140 years, thousands of employees, and millions of precision tools, gages, and saw blades later, the L.S. Starrett Company continues to manufacture the lion’s share of its tools here in the States.

Stihl USA

Founded by Andreas Stihl in 1926, Stihl designed and built the very first two-person electric chain saw. Over 90 years later, Stihl is represented in more than 160 countries with professional forestry and agriculture, landscape maintenance, and construction products.

In 1974, the Stihl family opened a 20,000 square foot manufacturing facility in Virginia Beach with 50 employees. Today, more than 2,000 employees work in over one-million-square-feet of operating space on the 150-acre Stihl Inc. Virginia campus.

Stihl builds nearly 100 different products from both domestic and foreign components right in this state-of-the-art facility. This includes gas and battery-powered blowers, string trimmers, hedge trimmers, pole and chain saws, multi-head units, shredders, and sprayers

Titan USA

Titan USA, based in West Springfield, Massachusetts, started around 50 years ago. The company prides itself on producing solid carbide, high-speed steel, and cobalt precision cutting tools. All are 100% Made in the USA. That includes endmills, micro endmills, thread mills, drill mills, drills, chamfer mills, taps and dies, reamers, burs, and countersinks.

Vaughan & Bushnell Mfg. Co.

In the 1800s, 18-year-old blacksmith Alexander Vaughan founded the company that now goes by Vaughan & Bushnell Mfg. Co. in Peoria, IL. The company started as a simple plumbing business but quickly relocated to Chicago where Sidney Bushnell joined the company to help it out following the devastating Chicago fire.

The company currently makes over 17 different types of tools in their Bushnell, Illinois manufacturing facility. That includes hammers, picks, mallets, hatchets, nail pullers, and pry bars. In addition, Vaughan & Bushnell acquired Dasco Pro and makes their punches, chisels, wrecking bars, and awls.

Viking Drill and Tool

Located in Saint Paul, Minnesota, Viking Drill & Tool has manufactured high-speed cutting tools since 1951. From the raw material to the finished cutting products, Viking designs, engineers, and manufactures cutting tools in their 74,000 square foot St. Paul facility.

Wilde Tool

Wilde Tool manufactures hand tools—and the entire start to finish process occurs at their manufacturing facility in Hiawatha, Kansas. You may have never heard of them. In fact, their primary business has them private-labeling tools for several national and international companies, mass merchandisers, and OEM’s.

The company started 95 years ago in Kansas City, Missouri, when brothers Paul and Otto Froeschl thought to angle the nose on ordinary straight-nose pliers 32 degrees to create greater leverage and gripping power. Thus was born the original Wilde Wrench, the first patented pair of angle nose pliers. The rest is literally history.

Wilton Tools

in 1941, Hugh W. Vogl, a Czech immigrant, founded the Wilton vise manufacturing company in Chicago, IL, naming it after the cross street where the original company building was located.

Years later, the manufacturing of Wilton industrial vises moved to Carpentersville, IL. There, the Wilton brand came alongside JET and Powermatic which, in 2014, became JPW Industries. When we asked Wilton what tools are Made in the USA, they responded with the Wilton Combo Pipe & Bench vises and Machinist Bullet Bench vises.

Wright Tool

Since 1927, the Wright Tool Company has manufactured quality hand tools for professionals. Even since striking the first forging in Barberton, Ohio, Wright Tools continue to be made in the USA. They continue to make all of their wrenches, ratchets, sockets, and attachments using U.S. steel. Precision heat treating and advanced manufacturing techniques likely contribute to the fact that Wright can offer a limited lifetime warranty on most of their hand tools.